1045 annealed steel charpy impact test|charpy impact test cheat sheet : Big box store The most common method is the notched-bar impact test for which two types of specimens prevail, Charpy and Izod. By subjecting a specimen to an impact load, it will fail if the load . Shop for Hartford 24" End Table AH300E by Winners Only at Bosler's Furniture & Mattress - Furniture and Mattress Store in Evansville, IN. (812) 476-8787 Evansville, IN

{plog:ftitle_list}

Find the best online casino Canada sites February 2024 - $15.

What is your minimum test temperature for CVN impact? Why is the 1045 steel being permitted when CAN/CSA G40.21 Grade 300W is specified? You can look at tempering .

high temperature ultrasonic thickness measurement

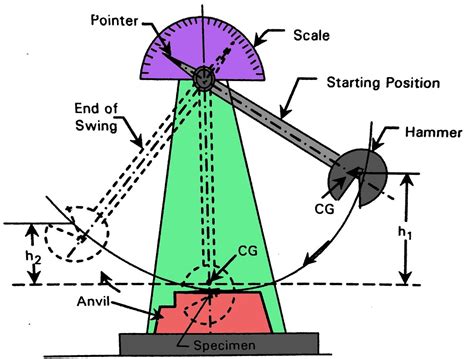

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .The most common method is the notched-bar impact test for which two types of specimens prevail, Charpy and Izod. By subjecting a specimen to an impact load, it will fail if the load .According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy . the production of reference Charpy specimens for the indirect verification of impact testing machines in accordance with ASTM E23-12c: two quenched and tempered 4340 steels (with different mechanical properties . steel is an 18 Ni maraging steel .

standard charpy impact test

impact testing of mild steel, the Charpy Impact Test can provide information on how much energy a specimen such as mild steel can absorb under an impact scenario. In this context, the following sections will present information on: 1) impact testing; 2) effect of . Figure 4 shows the characteristic microstructure of the AISI 1045 carbon steel in the as-received annealed condition. The matrix exhibits ferrite grains and pearlite colonies. . Figures 12 and 13, in a and c, show the curves obtained for the instrumented impact Charpy test for the AISI 1045 plates with hardfacing produced by means of GMAW-P .

To carry out a standard tensile test on specimens of a hot rolled steel (AISI 1045), Type 2024-T351 aluminum, polymers (UHMW-PE, acrylic) and, from the results, to determine the yield . Specimen (1/2 in. Diameter, ½ in. long or broken Charpy bars) steel, water quenched, air quenched, or furnace cooled (1 per student). . IMPACT TESTING OF . Charpy V-Notch impact energy on dual phase 590 steel as well as AISI-1018 structural steel is presented. Tests were conducted at temperatures ranging from −120 °C (−184 °F) to 90 °C (194 °F). Specimens oriented in both L–T and T–L directions were tested for the DP590. Corrections for the reduced thickness was made and justified.1. A tensile test, 2. A Rockwell hardness test. Also, in order to get a tangible perception of the relative properties of the three material conditions, we will manually bend rods and compare the relative loads required to initiate plastic deformation. 3. A Charpy Unotch impact test.We provide Charpy V-notch testing to ensure your steel purchases are suitable for your projects. Fast service & turnaround times. Request a free quote today! For Immediate Service, Call: 800-675-9929. . Charpy Testing for Your Steel Products. The Charpy impact test method, also known as the Charpy V-notch test, will determine the impact .

examples of charpy impact tests

charpy impact testing

WALDUN is one of the best AISI 1045 steel Manufacturer and Exporter in China.WALDUN is supplying with round,square,flat,block,and shaft etc.. 1045 steel is defined as medium carbon steel which has 0.43%-0.5% Carbon.It offers good weldability, good machinability, high strength and impact properties,but low in hardenability because of lack of .

Check the SAE 1045 Steel Chemical Composition, AISI 1045 offers high strength and good weldability. . Impact Charpy: 30: 30: 30: Elongationin 50mm % 14: 16: 7: Hardness HB: 210-245: 195-235 |185-230: . Ck45 Steel Annealing. Aspect Details; Purpose of Annealing: Softens surface hardness for improved machinability: Annealing Temperature: 820 .

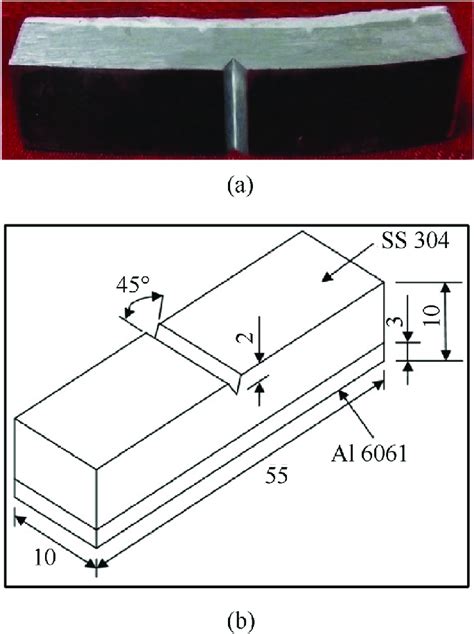

Optical microstructure of the full-annealed 1045 steel. Samples for Charpy impact test were machined following the requirement specified in ASTM E 23 (Type A). The Charpy impact tests were performed at room temperature using a standard Charpy pendulum machine with a capacity of 360 .

The fracture toughness was estimated from the results of Charpy tests performed on the heat-affected zone (HAZ) of SAE/AISI 1045 steel. In addition, finite element analysis was used to determine the stress state caused by four heavy vehicles (T3-S2-R4 type) localized on one side of the column.Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .Abstract: The Charpy impact test is a significant tool for the determination of fundamental properties for materials selection in mechanical designs, like the impact toughness and the brittle-ductile transition temperature. Charpy V-notch impact tests on 10 mm thick, Dual-Phase ferrite-perlite steel were evaluated at temperatures ranging from 90 ºC to -60 ºC.

Since fracture or failure behavior depends on temperature, Charpy impact tests are often performed in the entire operating temperature range. This shows at what temperature and to what extent the material becomes brittle (tough-to-brittle .The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. After

The AISI 1045 steel is treated by Annealing (Furnace cooling), Normalizing (room temperature), and Quenching (water). Then the samples were tested for hardness, tensile strength, and toughness (Charpy test). The results show that the tensile strength decreases by 12.4%, 6.33%, and 2.29% in annealing, normalizing, and quenching, respectively.AISI 1045 steel is a medium tensile steel supplied in the black hot rolled or normalized condition. It has a tensile strength of 570 - 700 MPa and Brinell hardness ranging between 170 and 210. . and high strength and impact properties in either the normalized or hot-rolled condition. . AISI 1045 is subjected to forging, annealing .

ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens. Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.2 Charpy impact test result of 1018 carbon steel bars Testing media/condition Impact energy (ft-Ib) 3 Testing temperature (C) -196 4 10.0 3.5 10.0 2.5 -78 4.5 Liquid nitrogen (N2()) Dry ice (CO2(s)) Room temperature Boiling water 21.0 24.5 31.5 74.0 33.0 116.8 5 20 105.0 7 100 3 26.0 89.0 119.2 119.5 WQ OQ AC FC Heat treatment conditions (pre annealed 960 C for 1 hr) 3 LO .Chapter 2 – Effects of Processing and Temperature on Charpy Impact Toughness in Metallic Glasses and Metallic Glass Matrix Composites Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

Medium Tensile Carbon Steel Bar 1045 Grade Data Sheet Controlled Intranet Document Authorised: John Pearson Page 1 of 4 Revised: 10/09/2021 . Full Annealing Normalising Hardening Quenching Medium Tempering 800 - 850°C 840 - 880°C 820 - 860°C Water or Oil 550 - 660°C . Impact Charpy (J) Up to 40 incl. 650 - 800 430 min 16 min 40 min .

charpy impact tester pdf

Microstructure and Mechanical Properties of annealed AISI 1045 Steel Abdulmula M. Mahaya1, . 2.2.4 Impact test . dimensions were tested using a Charpy impact machine of ZWICK type. The test is .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a). 304 Stainless Steel Using Charpy Impact Test Eman Mousa Alhajji North Carolina State University Department of Materials Science and Engineering MSE 355 Lab Report 201 A . (0.25 mm root radius) in the center of one face. The annealed 1018 steel samples were composed of iron with 0.18% C, 0.8% Mn, and 0.4% Si and had a BCC crystal structure and .Grade 410 stainless steel heat treatment includes annealing, hardening, tempering and stress relief. Annealing. Annealing temperature for wrought 410 stainless steel: Process (subcritical) annealing: Air cool from temperature 650-760 °C (1200-1400 °F). The maximum softness can be obtained by heating to the temperature at the upper limit of .

History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His work led to the creation of the Charpy impact test, which involved striking a standardized specimen with a .

charpy impact test dimensions

webcresce. no Brasil. Mensagens gratuitas. Diferente de outros sites de troca de casais, não pague nada no a3menage para enviar mensagens para quem você se interessou. .

1045 annealed steel charpy impact test|charpy impact test cheat sheet